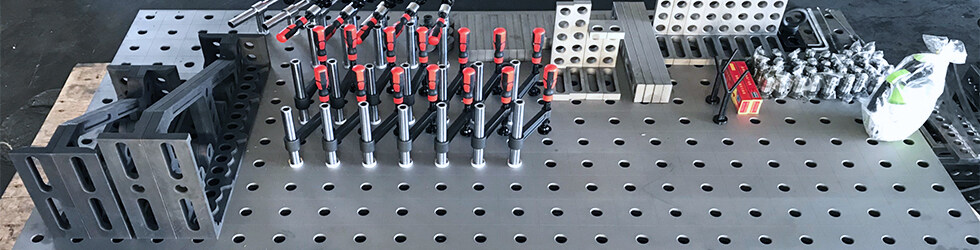

Modular clamp holding system

The 3D flexible modular welding fixture is a set of standardized, systematic, and universal fixtures.

It uses a workbench with a grid of standard holes on five working surfaces and a front grid line as a base, equipped with various standard modules for positioning. Quick connections are made through pins to achieve precise positioning and rapid clamping of workpieces of various shapes. It also allows for arbitrary combinations in three-dimensional space. The 3D modular welding tables are available in two series: D28 and D16. On the high-precision table surface, D28 round holes are evenly distributed every 100mm or D16 round holes every 50mm. These holes can be used to assemble various functional positioning modules and clamps. In addition to the tabletop, various functional modules include positioning blocks, angle blocks, pillars, adjustable-angle blocks, V-blocks, pins, various quick clamps, gap adjusters, and other auxiliary modules. The modules are cleverly designed for various combinations and repeated use.

1. Three-Dimensional: Unlike typical

fixtures that only have longitudinal and latitudinal directions, this platform

has two directions on the main surface and vertical installations around the

edges for a 3D combination.

2. Hole System: The primary feature

is the standard holes from the platform to the attachments, eliminating

traditional threads or T-slots. This design, coupled with quick-lock pins,

makes assembly faster and more accurate.

3. Combination: All attachments are

pre-made and can be freely combined and adjusted according to product needs.

4. Flexibility: The entire setup can

adapt to product changes, allowing one set of fixtures to meet the needs of

several or even dozens of products. This significantly speeds up product

development and prototyping, saving considerable manpower, materials, and

financial resources (environmentally friendly and low-carbon).

5. Welding: Designed specifically for manufacturing welded products, this universal fixture is convenient, flexible, and precise for welding, far more advanced than traditional welding methods.

6.Specifications:

The table can be customized to the required size: - 1000x500x200 - 1500x1000x200 - 2000x1000x200 - 2400x1200x200 - 3000x1500x200 - 4000x2000x200

7.Application Scope

With continuous industrial

development, the 3D flexible modular welding fixtures have been widely used in

equipment manufacturing and welding processing industries, completely changing

traditional industrial clamping and positioning methods and promoting the

development of new process methods. Through continuous efforts, we have gained

high market recognition. Nowadays, 3D flexible modular welding fixtures are

continuously used in welding production in industries such as machinery,

processing, rail transportation, automotive, motorcycle, shipbuilding, pressure

vessels, sheet metal processing, enclosures and cabinets, testing and

inspection, steel structures, and more, greatly improving production

efficiency.

Summary:

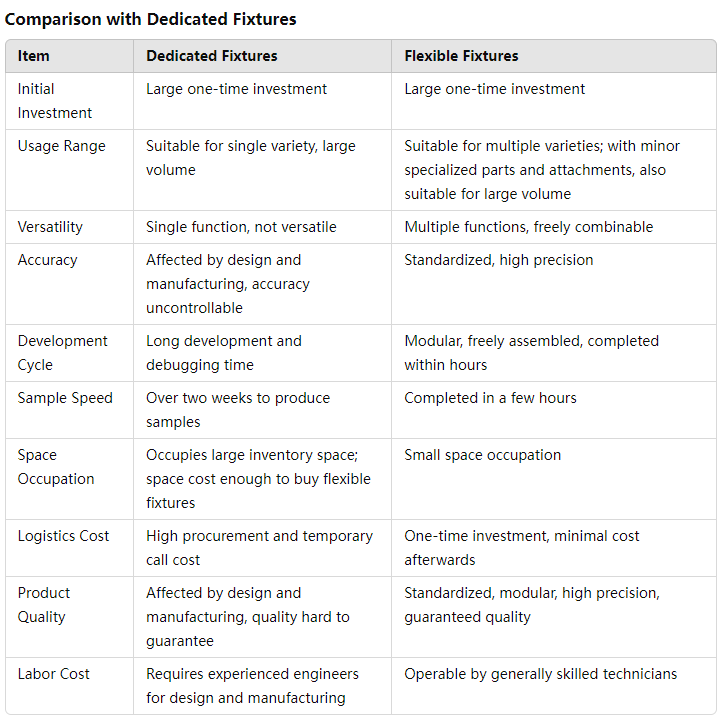

The multifunctional 3D welding

table from Dongguan Sanwei significantly reduces fixture costs through its

standardized, modular, and flexible design. It enhances production efficiency

and product quality, adapts to multi-variety production needs, shortens

development cycles, and reduces labor costs. Additionally, it optimizes space

and logistics costs, offering a comprehensive solution for modern welding and

manufacturing industries.

Follow us

Mia Liu

Mia Liu 400 004 8480

400 004 8480