Modular clamp holding system

■ Current

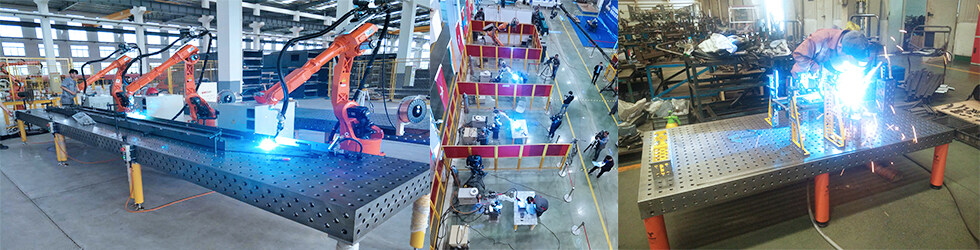

State of Modern Welding Production

With the increasing integration of robots and automation in modern industry, traditional assembly and welding tools are struggling to meet production demands. Improving production efficiency, reducing costs, and enhancing product quality have become primary goals for companies. Robots offer high efficiency, precision, and repeatability, which raises the precision requirements for fixture systems. Traditional fixtures are usually dedicated to specific products, requiring different fixtures for different workpieces, leading to long design and manufacturing cycles and higher production costs. This is particularly problematic for prototyping and small-batch, multi-specification production.

3D flexible modular welding fixtures address these deficiencies. Combined with some custom fixture attachments, they can achieve efficient, low-cost production. As a result, more companies are using these systems with robots to meet demands for efficiency, quality, economy, and rational production.

■ Overview

of Flexible Modular Fixtures

3D flexible modular welding fixtures are a 3D plane hole positioning and clamping system available in D28 and D16 series. They consist of standardized, serialized, and generalized modules. All modules are linked, fixed, and clamped using holes and quick-locking pins for rapid assembly. The main features include modularity, standardization, serialization, generalization, strong interchangeability, high stability, accuracy assurance, and cost-effectiveness. The system can be assembled in 2D and 3D configurations, similar to building blocks, making it simple, easy, and quick. Various clamping methods like hydraulic, pneumatic, and chain types can also be equipped as needed.

■ Advantages of 3D Flexible Modular Fixtures

1.

Efficient Production:

- High-precision welding products often

require quick prototyping and production, with frequent changes in shape and

size. Traditional welding fixtures take 1-3 months to produce, which is

insufficient for current production needs. Using high-precision standard

modules, positioning elements, and clamping elements, a welding fixture can be

quickly assembled in a few hours, meeting high-precision welding production

demands.

- Examples:

- MAN Bus in Germany reduced new product

development time from 11 months to 6 months using these fixtures.

- A Shanghai automotive parts manufacturer

reduced prototype time from 2-3 months to 7-15 days.

- An Anhui engineering machinery manufacturer reduced prototype time from 4 months to 30 days.

2.

Quality Products:

- High-precision welding products now

require accuracy comparable to machining. The fixtures must meet or exceed the

accuracy of the welded workpieces. Fixture materials like DIN ST53C

(high-quality alloy structural steel) and GGG50 (high-quality high-strength

ductile iron) are specially treated to prevent creep and splatter.

- With IT7 processing accuracy, the fixtures achieve IT8 or higher accuracy, suitable for high-precision welding processes.

3.

Low Economic Costs:

- Traditional welding fixtures, due to their

lack of generalization, have low usage rates, leading to high storage and

maintenance costs. In contrast, 3D flexible modular welding fixtures are

reusable, improving efficiency and quality, and providing significant economic

value.

- Cost Comparison:

- The price of one set of 3D flexible fixtures is equivalent to 4-5 sets of traditional fixtures. For companies needing more than 4-5 sets within a few years, the economic benefits are evident.

Comparison table of tooling and fixture investment costs

|

ITEM |

Design fee |

Charge for use |

Mainternance charges |

Training expense |

Advantages and disadvantages |

|

Multifunctional flexible combination

fixture |

No |

Multiple recycling use, high

utilization rate, almost no usage fee |

Module quality assurance, easy to

keep, and almost no maintenance fee |

Free long-term application training,

easy to learn and use |

Module spell group, fool type

operation, everyone can operate |

|

Non-standard special

fixtures |

More |

For each product, you have to pay

once for it |

Occupy a large storage space, not easy to

keep, accounting for 10-30% of the tooling cost |

Training once, the next time to

change the product and have to start the training, the operation technology

is not stable |

Experienced professionals are

required to operate, and they have to start learning to operate again |

4.

Rational Production:

- Dedicated fixtures are suitable for

large-batch production, while flexible modular fixtures cater to

high-precision, small-batch, and multi-variety production.

- Designing high-precision welding fixtures involves repetitive tasks, which flexible fixtures reduce by 85-90%, significantly enhancing efficiency.

5.

Broad Industry Application:

- Applicable in engineering machinery, rail

transit, shipbuilding, aerospace, automotive, cabinets, industrial pipelines,

various steel structures, pressure vessels, construction frames, scales,

automation integration, bicycle and motorcycle manufacturing, equipment

assembly, and testing.

- As industry standards rise, there is a

growing demand for comprehensive welding solutions. Dongguan Sanwei specializes

in the research and manufacture of welding automation machines and flexible

fixtures, offering solutions with Panasonic, OTC, Yaskawa, KUKA, FANUC, ABB

robots, fiber laser cutting machines, and welding fixtures.

Follow us

Mia Liu

Mia Liu 400 004 8480

400 004 8480