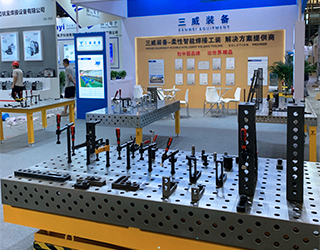

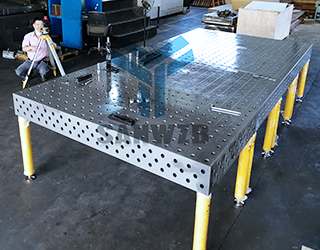

Choosing a well-known brand manufacturer ensures product quality is guaranteed.SANWZB is committed to producing the world's finest welding and fixture tables. We have taken our proprietary material, machining, and hardening processes to the next level with a new standard in table hardness and toughness.

Is the quality of the low-price 3 D welding tables guaranteed?How to distinguish the quality of 3 D welding tables?Users will test the problem before choosing the 3 D welding tables. The appearance quality of the 3 D welding tables refers to the table appearance roughness, defects, scale error, shape error, insufficient surface thickness, and the cast iron tooling platform should also see whether there are casting pores and sand holes, etc

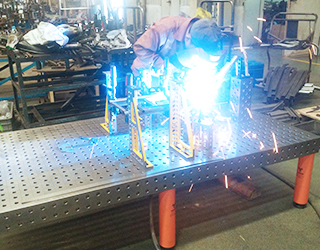

With the increasing integration of robots and automation in modern industry, traditional assembly and welding tools are struggling to meet production demands. Improving production efficiency, reducing costs, and enhancing product quality have become primary goals for companies. Robots offer high efficiency, precision, and repeatability, which raises the precision requirements for fixture systems.

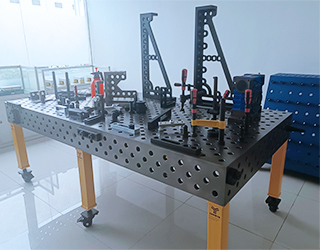

The 3D flexible modular welding fixture is a set of standardized, systematic, and universal fixtures. It uses a workbench with a grid of standard holes on five working surfaces and a front grid line as a base, equipped with various standard modules for positioning. Quick connections are made through pins to achieve precise positioning and rapid clamping of workpieces of various shapes.

Adopting Flexible Welding Fixtures for Custom Electric Vehicle Full Load-Bearing Frames is Inevitable , which is recognized as one of the safest structural technologies. However, the deformation control and rapid transformation of the frame welding of fully bearing electric vehicles have always been the difficulties in the manufacturing of new energy buses. And at present, there are more and more customized cars, the traditional special tooling has been unable to adapt to the changes of models, so the use of multi-functional flexible group of welding tooling has become an imperative trend.

|

Home Previous Next End Total:5Item |