Multi-function 3D welding table

Modular clamp holding system

Modular clamp holding system

Hotline:400-004-8480

| The optimum 3D welding table for every application, | ||||||

| - The SANWZB® welding tables. | ||||||

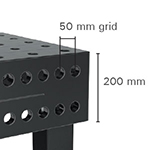

| With this system, you can set and fix the specified sizes for any work piece quickly and precisely. | Standard grid | Diagonal grid | ||||

| Welding tables come in a variety of sizes

to suit your unique fabrication needs. The five face design of the table,

reinforcements underneath creates an extremely rigid table surface. A plasma

nitride finish comes standard on all tables for a work surface extremely

resistant to wear, deformation, corrosion, and weld spatter. The plasma nitriding welding tables,The highest hardness can reach the HV 640. |

|

|

|

|||

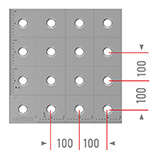

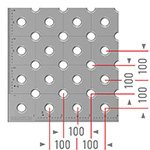

| ▪ System hole distribution : ① Standard grid:100 x 100 (mm) Code: KD, ② Diagonal grid 100 x 100 (mm) Code: XD | ||||||

| ▪ Material identification code: 0 - steel, 1 - HT300 Cast Iron, 2 - 304 stainless steel, | ||||||

| ▪ Support foot type:Square support legs, Frame support, Lift (hydraulic) | ||||||

| ▪ Description of the surface treatment code of the welding table(The last two digits of the product code) | ||||||

| Standard grid: | Diagonal grid: | Diagonal Grid Patterns | ||||

| B0 - Painting on non-working surface(or Color of the material) | X0 - Painting on non-working surface(or Color of the material) | Work holes are 22 mm diameter and spaced 100 mm apart. The diagonal grid pattern provides 80-90% more fixture locations on the top face of the table for even greater flexibility. | ||||

| B1 - Phosphating/Blackening B2 - Plasma Nitride | X1 - Phosphating/Blackening X2 - Plasma Nitride | |||||

| B3 - Nitriding and blackening B4 - Hard Chrome plating | X3 - Nitriding and blackening X4 - Hard Chrome plating | |||||

Product details

Follow us

sanwzb

sanwzb 400-004-8480

400-004-8480